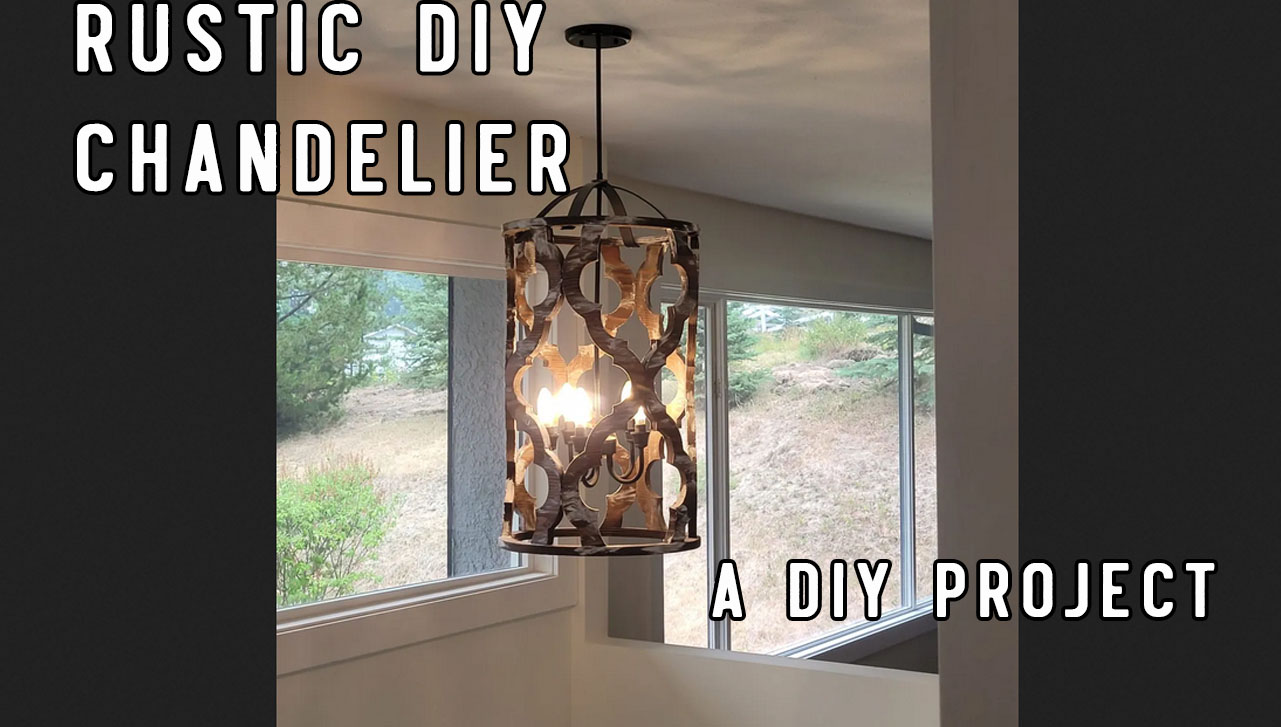

The lighting that you choose can make a dramatic difference in your space, but it can be expensive.

Enter my DIY chandelier project.

When we were renovating our house, we needed a new chandelier for the area in the landing by our front door.

Naturally, my wife started looking around at different lighting options.

It wasn’t long before she found an amazing french country chandelier.

The only downside?

It was $1200USD plus shipping.

Soooo …it wasn’t really in the budget.

But as I started looking at the chandelier, I had the devious little idea that I might be able to make one.

So I started investigating and got after it.

The Story

The nice thing about this project was that we were able to use materials we had lying around.

A scrap piece of 3/4″ plywood made up the bulk of the project, and we had stain, drywall mud & glue left over from other projects as well.

Repurposing the old chandelier light bulb fixture helped as well.

I the only things I had to pay for were the 2 laser cut templates I used as guides and some flat black spray paint.

Oh and I bought myself a router table.

I found a used one not far from where we lived for $150.

It included a Freud router & table, a moveable base and 3 boxes of different router bits.

With a price like that, I remember thinking that it was that it had to be stolen.

But I thought it was worth checking out that night after work anyway.

As luck would have it, we had to drive out in the middle of a storm that featured incredible winds, and monsoon-like rains in near complete darkness.

Between the black skies, rain and the headlights of the oncoming vehicles on the highway, visibility had dropped to almost zero.

If driving blind in a storm wasn’t bad enough, when we eventually found the address off of a tucked away backstreet in a sketchy neighborhood, I thought this whole operation might not end well.

When the door opened under my knock, the guy inside explained that he was a heavy duty mechanic who worked in different fly-in camps and that he was moving.

He didn’t want to have to pack the router table up and drag it to his new place, so he was getting rid of it.

The guy seemed decent enough and I felt his story seemed legit, so I paid the man his money and we loaded the table into the back of the truck.

Then we fought our way back home through the wind, rain and increasingly depressing darkness.

I guess sometimes there’s still a price to be paid even if you find a good deal.

The project itself went pretty smoothly once I had everything drawn up and the templates were made and everything came together as planned.

If You Want to Follow Along..

There are a few things that you’ll need if you want to follow along and do this project.

And wherever possible, I’ve tried to include links to where you can buy them online in order to save you some time.

Oh, and some of the links might be affiliate links so if you buy through them I might earn a small commission (at no additional cost to you).

It doesn’t cost you any more but it helps but a few more cents towards our next DIY project.

So without further ado, here’s the list:

- Jigsaw – This is a crucial tool on this project. If you don’t have one, you won’t be able to follow along. I recommend using a cordless one. Otherwise you can end up stepping on the cord as you’re cutting and it can ruin your cut.

- Jigsaw Blades. I could’ve left this one out, but having dull jigsaw blades is terrible. I like this set that comes with a hard case. That way I can just throw the whole case in my bag and it’s all there.

- Plywood. For this project, we used basic 3/4″ plywood. Nothing fancy there.

- Wood stain. I recommend picking up at least 2-3 small tins of different stain colors for your project. You’ll want to do some samples before coating your final project.

- Glue. You can use regular old wood glue if you want. But for me, I always use InstantBond. The stuff is freakishly strong and bonds within a couple seconds. I couldn’t believe how fast it cured once sprayed with the activator. One time when making cabinets (see this post here), I accidentally placed a piece of trim in the wrong spot. Well, in trying to pry the two pieces of wood apart I ended up de-laminating the plywood. (Like where the individual strips of wood that make up plywood pulled apart instead of the 2 pieces of wood that were glued together with the InstantBond glue.) The stuff just wouldn’t let go.

- Table Saw. You might be able to get away with just using the jigsaw. But it will make things a bit easier when you go to rip an angled cut on the curved sections of the chandelier.

- Drywall mud or spackle. We used this to add a bit of a shmear look to ours. But you can leave this off if you’d rather just paint or stain it.

- Router. You’ll need either a hand-held router or a router table. Using a router table will make your life easier. But you can do it with a hand-held if you need to. I find a router table makes your life a lot easier. You don’t need it for every DIY project you do. But when you need it, it sure makes life a lot easier.

- Double sided tape. You’ll use this to fasten your template to the wood parts you’re cutting. More on this later.

That’s about it. Other than that we’re ready to get started and design your chandelier.

The Design Process

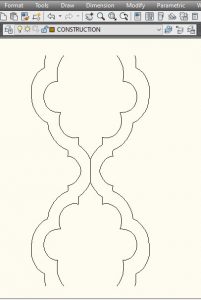

Basically what you need to do is figure out the size and shape of your inner sections of the chandelier.

Luckily for me, I use Autocad to design and lay these sort of things out.

It makes life a lot easier for me rather than trying to do maths.

For me, I drew out the general shape of the inner parts and scaled it to the height that I wanted.

I ended up with something like this:

Once I had the general shape done, I created a cut file for one of the sides and had it laser cut out of steel so I could use it as a template.

Then I laid out how the chandelier sides would all look so I could figure out how many of these side pieces I needed to make. This was all based on the approximate width of the chandelier I was looking to make.

I also drew the circle you see above and had a steel ring laser cut as well. (So I could use this as a template to cut my wood rings to size.)

Once I had the templates back from the laser cutter, I traced around the templates on the plywood and then cut the shapes out with the jig saw.

When I cut the shapes out, I made sure to leave about 1/8″-1/4″ of extra material on each side.

By doing this, I could fine-tune the shape and get it exactly by using the router table.

Once I had my over-sized shapes cut out, I used 2 sided tape and fastened the metal template on top of one of the wooden shapes that I’d cut out.

Using a straight cut router bit with a guide bearing on the top of it, I used the router table to follow the contour of the metal.

This way, the router would remove the extra 1/8″x1/4″ of wood.

I repeated this process for both top and bottom rings as well as all of the side chandelier pieces.

Then I went back to Autocad and found out what angle was where the inside edges of the interior chandelier part would join together once they were stood up.

I set the table saw as close as I could to that angle and cut the middle sections so they joined at the correct angle.

We then glued the pieces all together and came up with this:

I highly recommend getting someone to help you when you’re gluing it all together.

The Manual Alternative

If you don’t have a laser cutter (or don’t want to pay for a piece to be cut), there is another way.

You can do it manually.

For this I’d recommend you draw out your shapes on cardboard and cut them out.

Then make a wooden template out of 1/2″ plywood for the parts. Cut the template part as carefully as possible as it will be used to make exact copies of the other pieces.

Use the 2 sided tape to attach your wooden template to the rough cut parts.

Then rough cut the remainder of the pieces leaving about 1/8″-1/4″ extra material as before and then use the flush cut router bit with guide bearing on top to remove the extra material & follow the template.

It might be a bit trickier to figure out your angles and how big to make your rings, but with a little patience I’m sure you can get it.

Finishing the Project

Once everything was glued together, we stained the newly minted chandelier and added the drywall mud to it to give it a bit of a textured shmear like look.

At this point you may be wondering… but what about the light fixture itself?

All we did for that was reuse the light bulb holders from an old hanging chain light chandelier.

To attach that part to the wood, I hand-bent some 1″ wide steel flatbar to shape and screwed it to the top of the wooden chandelier part.

From there, you could use a chain to hang it, or you could use threaded rod (available here) as I did.

We finished everything off with some black spray paint and, as a Frenchman looking at his French Country Chandelier might say: “Voila!”

Final Thoughts on the DIY Chandelier

Overall, I think this project turned out pretty well.

In fact, we regularly get a lot of compliments from our neighbors and people who see the chandelier from the street.

But this project allows for a lot of different customization in terms of the overall design, look and feel of it all.

So you can make something to fit your space perfectly.

And now you don’t have to pay full price for a nice chandelier 😁